-

I-SA588 SA387 iPlayiti yentsimbi yengxubevange

Umboniso wemveliso:

Ngokomxholo wezinto zealloyi zahlulwe zibe:

intsimbi ephantsi ye-alloy (inani elipheleleyo lezinto ze-alloy lingaphantsi kwe-5%),

Intsimbi ye-alloy ephakathi (5% -10% yezinto ezipheleleyo ze-alloy)

Intsimbi ye-alloy ephezulu (into yonke ye-alloy iphezulu kune-10%).

Ngokokwakheka kwe-alloy element ibe:

Intsimbi yeChromium (Cr-Fe-C)

Intsimbi yeChromium-nickel (Cr-Ni-Fe-C)

Intsimbi yeManganese (Mn-Fe-C)

Intsimbi yeSilicon-manganese (Si-Mn-Fe-C)

-

Ipleyiti ekwaziyo ukuNxitywa, ipleyiti eNxhathisa iMozulu

Umboniso wemveliso:

Ipleyiti yensimbi engagugiyo ihlanganiswe ngamacandelo amabini: ipleyiti yentsimbi ephantsi-carbon kunye ne-alloy wear-resistant layer.Umaleko we-alloy ongagungqiyo ngokuqhelekileyo yi-1 / 3 ~ 1 / 2 yobukhulu obupheleleyo.Xa usebenza, i-matrix ibonelela ngokusebenza okubanzi njengamandla, ukuqina kunye neplastiki, kunye ne-alloy wear-resistant layer inikezela ukuxhathisa ukunxiba ukuhlangabezana neemfuno zeemeko zokusebenza ezichaziweyo.

I-alloy wear-resistant layer yi-alloy ye-chromium, kunye ne-manganese, i-molybdenum, i-niobium, i-nickel kunye nezinye izinto ze-alloy nazo zongezwa.I-carbide kwi-metallographic tissue isasazwa kwi-fiber shape, kwaye i-fiber direction ye-fiber i-perpendicular kumphezulu.I-microhardness ye-carbide inokufikelela ngaphezu kwe-HV1700-2000, kwaye ubunzima bomhlaba bunokufikelela kwi-HRC 58-62.I-alloy carbide inozinzo olomeleleyo kubushushu obuphezulu, igcina ubulukhuni obuphezulu, kodwa ineempawu ezilungileyo ze-antioxidant, ngaphakathi kwe-500 ℃ yokusetyenziswa okuqhelekileyo ngokupheleleyo.

-

SA516 Gr60 Gr70 SA387Gr22CL2 Icwecwe lesikhongozeli

Umboniso wemveliso:

Ipleyiti yesikhongozeli isetyenziselwa ukusetyenziswa kwenqanawa yoxinzelelo

-

S235JR S275JR S355JR Carbon Steel Plate

Umboniso wemveliso:

Iipleyiti zentsimbi zohlulwe zibe ziipleyiti eziqengqelekayo ezishushu nezibandayo.

Ngokweentlobo zentsimbi, kukho intsimbi eqhelekileyo, intsimbi ekumgangatho ophezulu, intsimbi exutywe nentsimbi, intsimbi yasentwasahlobo, intsimbi engenanto, intsimbi yesixhobo, intsimbi ekwaziyo ukumelana nobushushu, intsimbi yokuthwala, intsimbi yesilicon kunye neshiti lentsimbi ecocekileyo.

Umgangatho ophezulu we-carbon structural steel ungahlulwa ube ngamacandelo amathathu ngokwemixholo yekhabhoni eyahlukeneyo: i-carbon steel low (C 0.25%), i-carbon steel medium (C yi-0.25-0.6%) kunye ne-carbon steel ephezulu (C & gt; 0.6%).

Umgangatho ophezulu we-carbon structural steel wahlulwe kwi-manganese eqhelekileyo (0.25% -0.8%) kunye ne-manganese ephezulu (0.70% -1.20%), le yokugqibela ineempawu ezintle zoomatshini kunye neepropati zokucubungula.

-

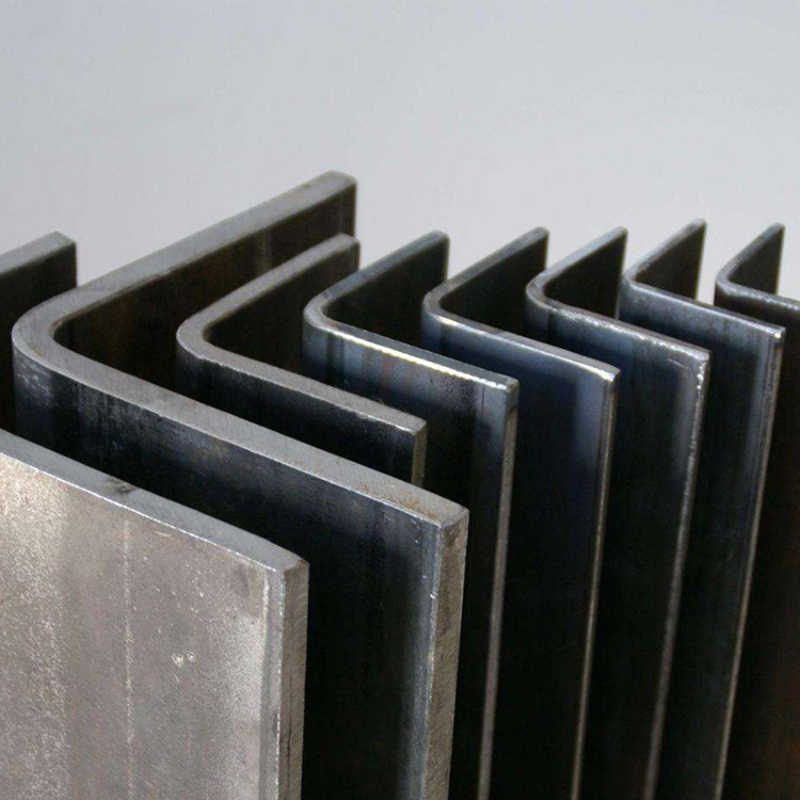

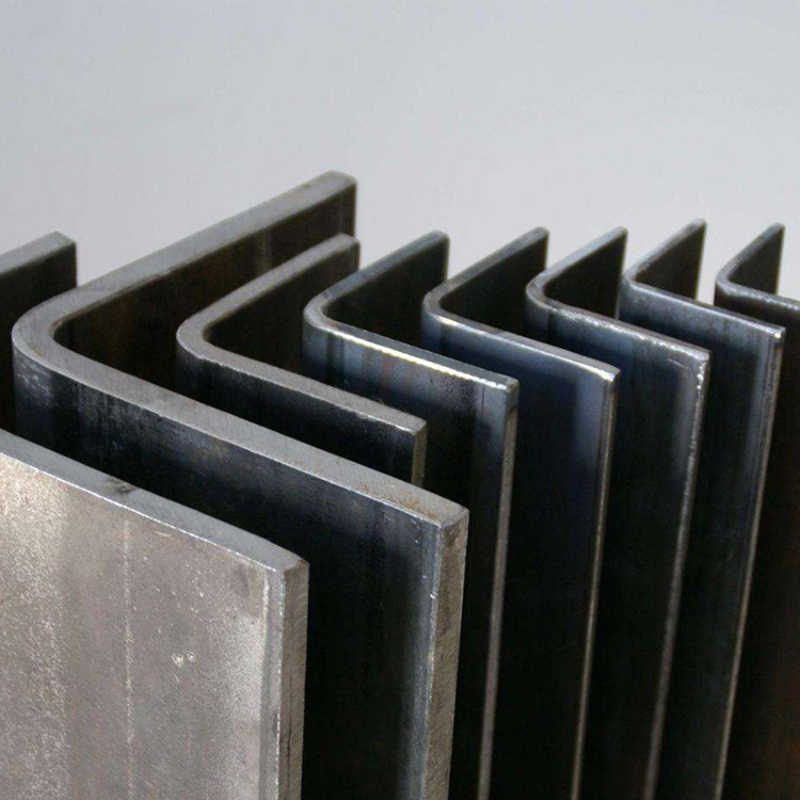

ST37 ST52 S235 JRS275 A36 A53 Intsimbi yeAngle

Umboniso wemveliso:

I-Angle steel yintsimbi emile okwe-L, idla ngokwenziwa ngokugoba okushushu okanye ukugoba okubandayo.Ubude kunye nobukhulu bentsimbi ye-angle ingenziwa ngokwezifiso njengoko kufuneka.

Inkqubo yemveliso yentsimbi yeAngle ngokubanzi ibandakanya ukuqengqeleka okushushu kunye nokugoba okubandayo.Intsimbi ye-Angle eshushu ephothiweyo kukufudumeza i-billet kwiqondo lobushushu elithile ngendlela ye-roller emva kokucofa ukubumba, ukusebenza kakuhle kwemveliso kuphezulu, kodwa ixabiso liphezulu kakhulu.Ukugoba okubandayo kungomatshini ukwenza ipleyiti yentsimbi yangaphambili, ixabiso liphantsi kodwa ukusebenza kakuhle kwemveliso kuphantsi.

-

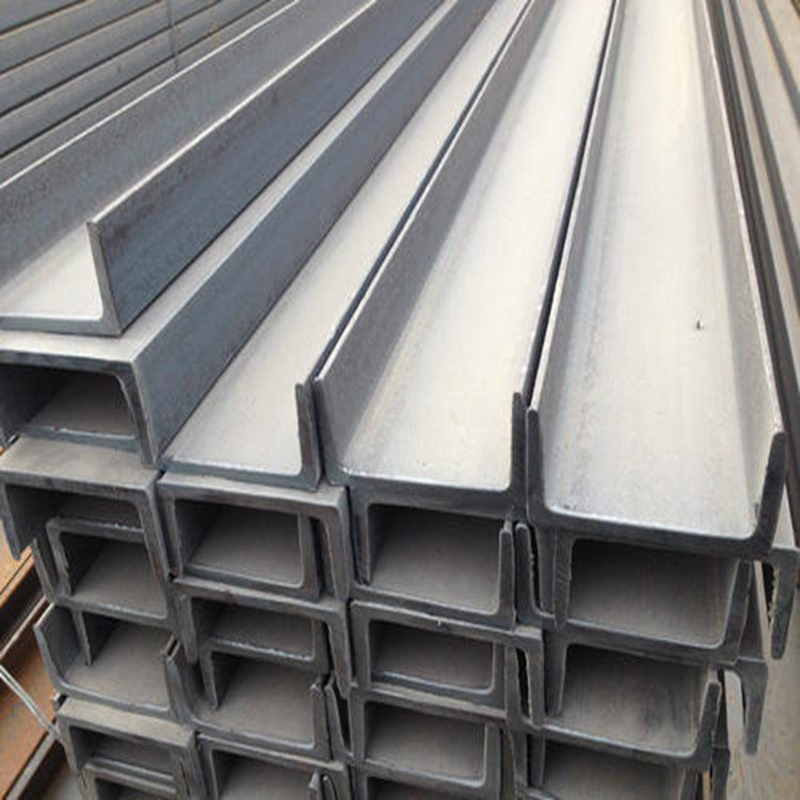

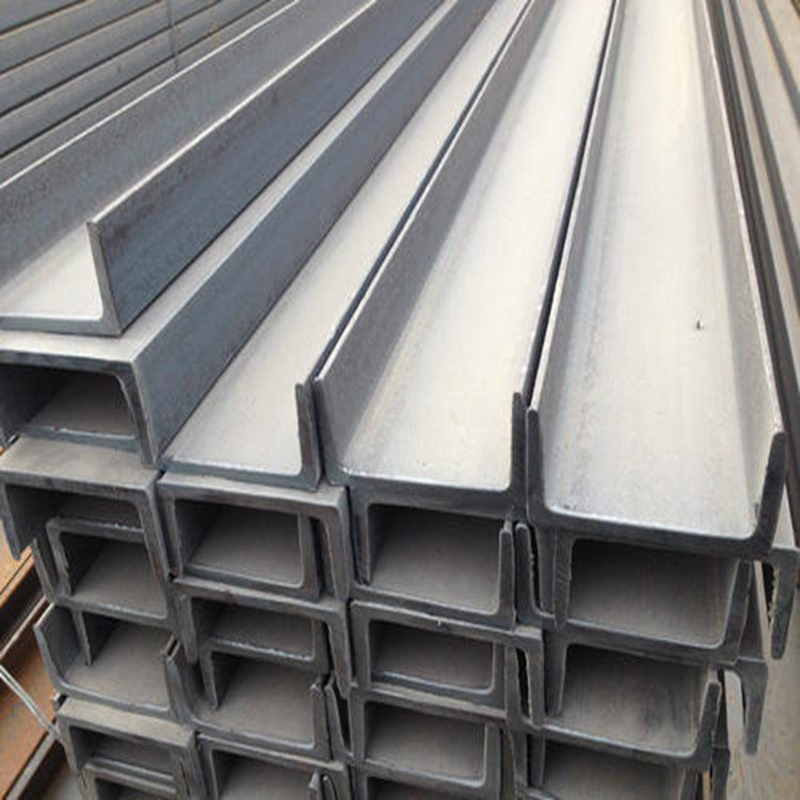

304, 310S, 316, 347, 2205 iStainless Channel Steel

Umboniso wemveliso:

Intsimbi ye-stainless steel groove icandelo elide le-groove emise okwentsimbi, lilolwakhiwo kunye ne-carbon mechanical structure steel, licandelo eliyinkimbinkimbi yecandelo lentsimbi, icandelo layo liyimilo ye-groove.Ubude kunye nobukhulu bentsimbi yombhobho bunokwenziwa ngokwezifiso njengoko kufuneka.

Inkqubo yemveliso yentsimbi yensimbi engenasici ibandakanya iindlela ezimbini: ukuqengqeleka okushushu kunye nokugoba okubandayo.Hot rolling groove Angle intsimbi kukufudumeza billet kubushushu obuthile ngokusebenzisa umjelo roller ngokucinezela ukubumba.Ukugoba okubandayo kusetyenzwa ngomatshini ukwenza ipleyiti yentsimbi yokulungisa kwangaphambili.

Intsimbi yokukhongozela yentsimbi yenziwe ngentsimbi eshushu esongwayo nebandayo ngokugoba nokwenza.Inecandelo le-groove kwaye liyinto eqhelekileyo kwiimveliso ezininzi zetsimbi.Isetyenziswa ngokubanzi kulwakhiwo, ukwenziwa koomatshini, i-petrochemical, ishishini kunye nemimandla yezothutho.

-

304, 310S, 316, 347, 2205 Intsimbi yeBha eStainless Round

Umboniso wemveliso:

Intsimbi ye-Stainless Round yintsimbi eqinileyo ye-cylindrical, ububanzi bayo bunokuthi buyilwe ngobukhulu obuhlukeneyo ngokweemfuno zemveliso.Inkqubo yokucubungula ibandakanya ukuqengqeleka okushushu, umzobo obandayo, ukubumba kunye nonyango lobushushu kunye nezinye iindlela.Phakathi kwabo, ukutshisa okutshisayo yinkqubo esetyenziswa ngokuqhelekileyo, enokuvelisa intsimbi ejikelezileyo kunye nobubanzi obukhulu.Inkqubo yokudweba ebandayo inokuvelisa i-diameter encinci kunye nokuchaneka okuphezulu kwentsimbi ejikelezayo.

-

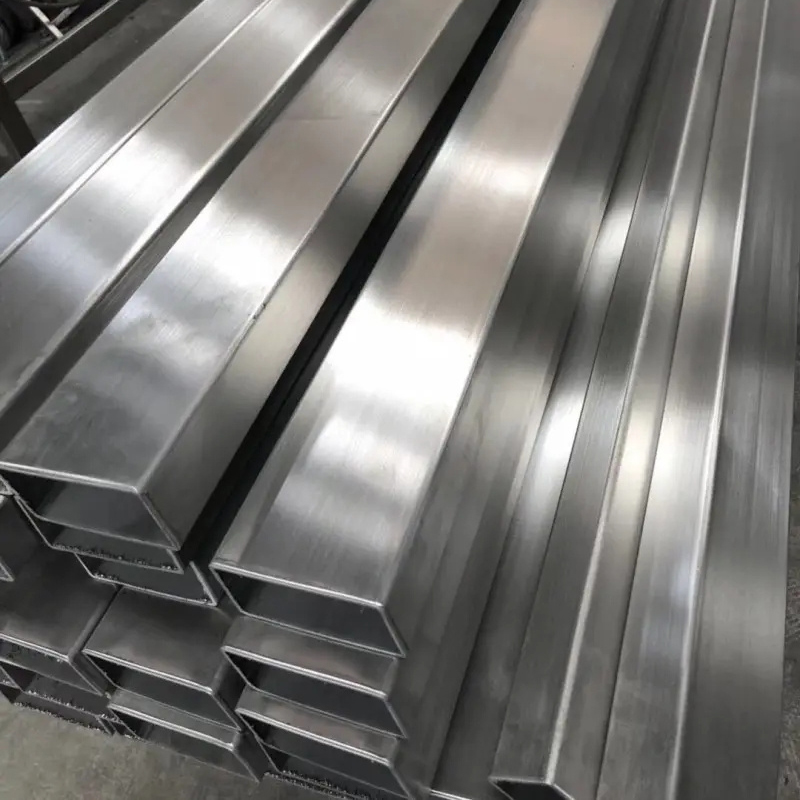

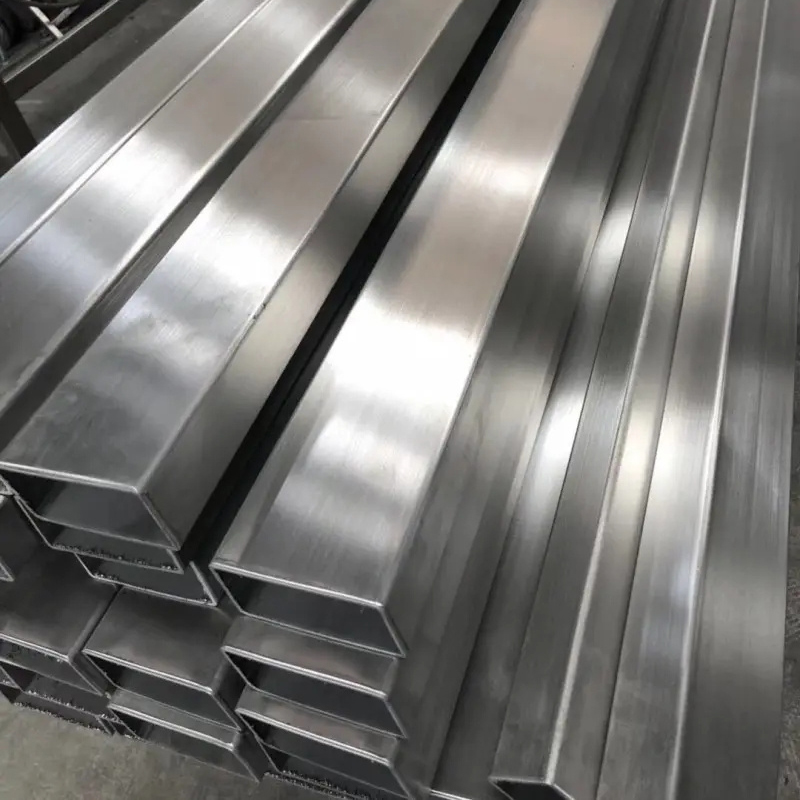

St52 A178 A53/304 316 347 Welded Square/Rectangular Tube

Umboniso wemveliso:

Umbhobho wesikweri ngumbhobho osikweri osikweri onomngxuma wokukhanya obhityileyo-udonga lombhobho wentsimbi, okwaziwa ngokuba yintsimbi yokugoba iprofayile.Ngumcu oqengqelekayo oshushu okanye obandayo oqengqelekayo okanye ikhoyili njengesiseko semathiriyeli ngokugoba okubandayo kwaye emva koko yenziwe nge-welding ephezulu ye-welding yecandelo lesikwere ubukhulu bemilo yentsimbi.Ngaphandle kodonga lokutyeba kunye nokuqina, ubungakanani bekona kunye nokuguda kwecala bonke bafikelele okanye bagqithise kwinqanaba lokumelana ne-welded ebandayo eyenza umbhobho wesikwere.Iipropathi ezibanzi zoomatshini, ukuwelda, iipropathi zomatshini ezibandayo kunye nezishushu kunye nokumelana nomhlwa zilungile, kunye nokuqina okuhle kobushushu obuphantsi.

Ukusetyenziswa kwemibhobho yokwakha, ukuveliswa koomatshini, iiprojekthi zolwakhiwo lwentsimbi, ukwakhiwa kweenqanawa, inkxaso yombane welanga, ubunjineli besakhiwo sentsimbi, ubunjineli bamandla ombane, iplanti yamandla, ezolimo kunye noomatshini bekhemikhali, udonga lomkhusane weglasi, i-chassis yemoto, isikhululo seenqwelomoya, ukwakhiwa kwebhoyila, iiroli zendlela, izindlu. ukwakhiwa, iinqanawa zoxinzelelo, iitanki zokugcina i-oyile, iiBridges, izixhobo zesikhululo samandla, ukuphakamisa oomatshini bokuthutha kunye nomnye umthwalo ophezulu wesakhiwo se-welding, njl.

-

St37 St52 A214 A178 A53 A423 Umbhobho oshiselwe ngeGati, ERW

Umboniso wemveliso:

Umbhobho owenziwe ngesinyithi oshushu-dip kukwenza isinyithi esinyibilikisiweyo kunye ne-iron matrix reaction kwaye uvelise umaleko we-alloy, ukuze i-matrix kunye nomaleko wokugquma zidityaniswe.Hot galvanizing yintsimbi umbhobho kuqala, ukuze ukususa oxide yentsimbi phezu komhlaba umbhobho yentsimbi, emva pickling, ngokusebenzisa isisombululo ammonium chloride okanye zinc chloride okanye ammonium chloride kunye nezinc chloride isisombululo exutywe itanki, kwaye emva koko ithunyelwe kwi eshushu. dipha itanki yokucoca.I-Hot-dip galvanizing ineenzuzo zokugquma okufanayo, ukunamathela okuqinileyo kunye nobomi benkonzo ende.Ukusabela okuntsonkothileyo ngokomzimba kunye neekhemikhali kwenzeka kunye nesisombululo esityhidiweyo sombhobho wensimbi owenziwe ngesinyithi oshushu-diphu, usenza umaleko ongagugiyo kunye nokuqina kwe-zinc-enye yentsimbi yealloyi.I-alloy layer idityaniswe ne-zinc ecocekileyo kunye ne-tube matrix yensimbi, ngoko ke ukuxhathisa kwayo kunamandla.

-

API 5L 3PE Q345 St37 St52 Welded Pipe, ERW, Spiral Welded Pipe

Umboniso wemveliso:

I-billet esetyenziselwa i-welding yentsimbi yombhobho yintsimbi yentsimbi okanye i-strip steel, ngenxa yenkqubo yokudibanisa eyahlukileyo, ihlulwe ibe ngumbhobho we-furnace welding, i-welding yombane (i-resistance welding) umbhobho kunye nombhobho we-arc welding ngokuzenzekelayo.Ngenxa yeendlela ezahlukeneyo zokuwelda, yahlulwe yaba yimibhobho edityanisiweyo ethe tye kunye nemibhobho edityanisiweyo.Ngenxa imilo yayo ekupheleni yahlulwe kwisetyhula welded umbhobho kunye nohlobo ezahlukeneyo (isikwere, flat, njalo njalo) welded umbhobho.

-

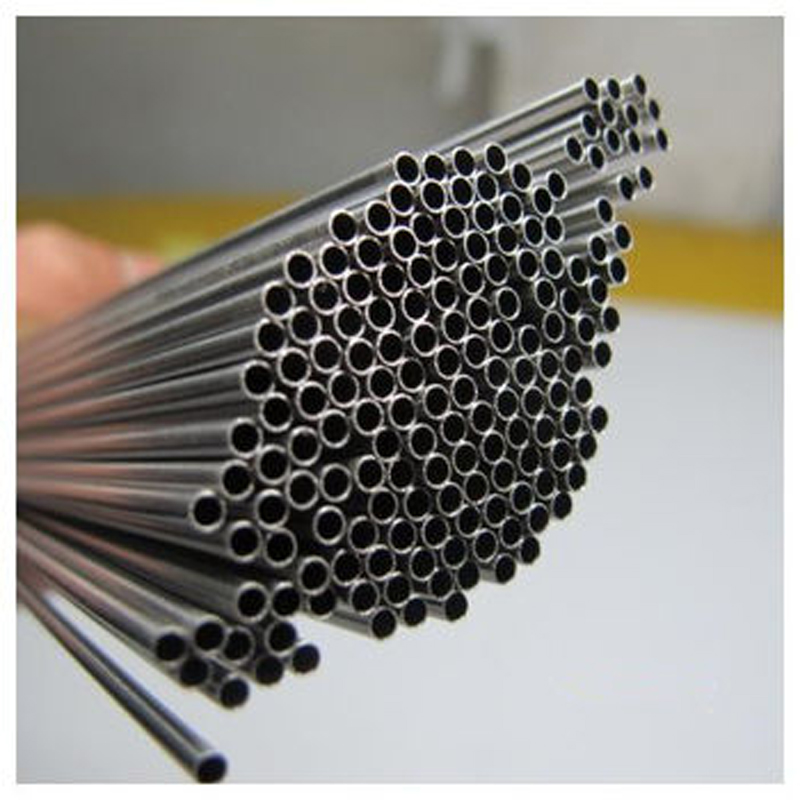

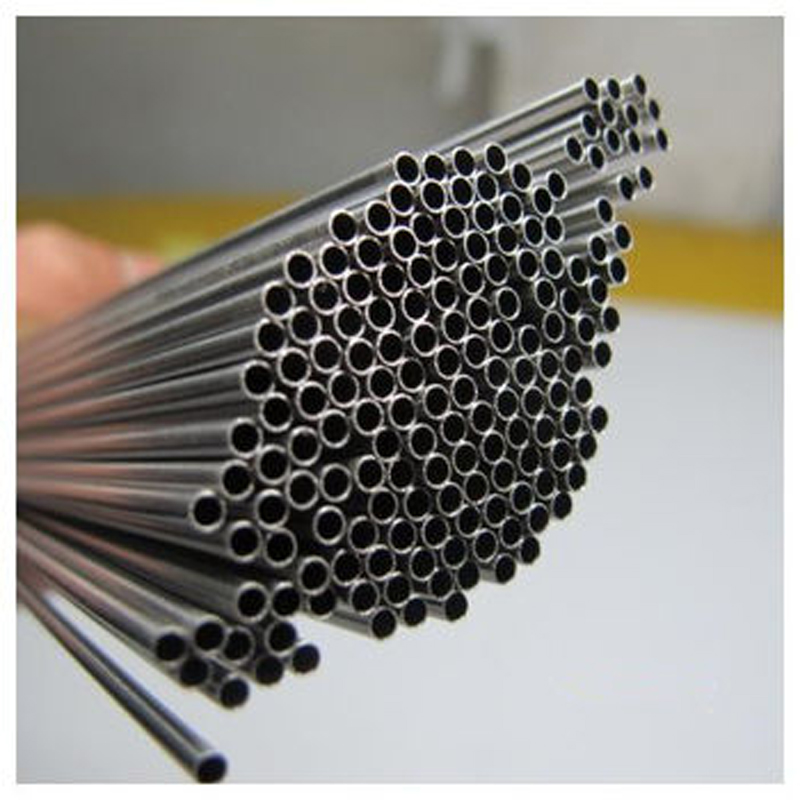

316L 347H S32205 Umbhobho wentsimbi ongenamthungo

Umboniso wemveliso:

Ulwahlulo lombhobho wensimbi engenasici: umbhobho wentsimbi engenamthungo kunye nombhobho wentsimbi odityanisiweyo (enemithungo) iindidi ezimbini ezisisiseko.Ngokwemilo yangaphandle yedayamitha yombhobho wentsimbi inokwahlulwa ibe ngumbhobho ongqukuva kunye nombhobho omilise okhethekileyo, isetyenziswa kakhulu ngumbhobho wentsimbi ojikelezayo, kodwa kukho ezinye isikwere, uxande, isemicircular, hexagonal, unxantathu olinganayo, octagonal kunye nezinye ezikhethekileyo. umbhobho wentsimbi omile.

Umbhobho wensimbi engenamthungo wenziwa ngentsimbi yentsimbi okanye umbhobho oqinileyo webillet ngokugqobhoza, kwaye emva koko ngokuqengqeleka okushushu, okuqengqelekayo okuqengqelekayo okanye okubandayo okwenziweyo. -

201, 304, 347H, S32205 Stainless Steel Welded Umbhobho/ ERW

Umboniso wemveliso:

Ulwahlulo lombhobho wensimbi engenasici: umbhobho wentsimbi engenamthungo kunye nombhobho wentsimbi odityanisiweyo (enemithungo) iindidi ezimbini ezisisiseko.Ngokwemilo yangaphandle yedayamitha yombhobho wentsimbi inokwahlulwa ibe ngumbhobho ongqukuva kunye nombhobho omilise okhethekileyo, isetyenziswa kakhulu ngumbhobho wentsimbi ojikelezayo, kodwa kukho ezinye isikwere, uxande, isemicircular, hexagonal, unxantathu olinganayo, octagonal kunye nezinye ezikhethekileyo. umbhobho wentsimbi omile.

Ngokusetyenziswa, yahlulwe kumbhobho odityanisiweyo ngokubanzi, umbhobho wokutshintshisa ubushushu, umbhobho wecondenser, umbhobho odityanisiweyo, umbhobho we-oksijini welding, umbhobho wocingo, umbhobho odityanisiweyo we-metric, umbhobho we-idler, umbhobho wempompo onzulu, umbhobho wemoto, umbhobho we-transformer, umbane. ukuwelda umbhobho obhityileyo eludongeni, umbhobho wokuwelda ombane kunye nombhobho we-spiral welding.