-

I-alloy Steel Pipe Fitting A234WP12 P1 PA22 P5

Umboniso wemveliso:

Izixhobo ze-Alloy Steel Pipe ziyigama eliqhelekileyo lamacandelo adibanisa, ukulawula, ukutshintsha, ukuguqula, ukutywinwa kunye nokuxhasa inkqubo yombhobho.Ukufakwa kombhobho yinxalenye edibanisa umbhobho kumbhobho.Izifakelo zombhobho woxinzelelo oluphezulu zifanelekile kwisixhobo somoya woxinzelelo oluphezulu, iikhemikhali zobushushu obuphezulu kunye nombhobho woxinzelelo oluphezulu, iplanti yamandla kunye neenqanawa zoxinzelelo lweplanti yamandla enyukliya, izixhobo zebhoyila ezinoxinzelelo oluphezulu kunye nokunye okusingqongileyo okukhethekileyo.Ukufakelwa kwemibhobho kusetyenziswa kakhulu kwiinkalo ezininzi zobunjineli ezifana nokwakha, ishishini lemichiza, imigodi kunye namandla.Indima yayo ebalulekileyo akufanele ihoywe.

-

Ityhubhu yentsimbi engenamthungo yokutshintsha ubushushu / umbhobho webhoyila

Umboniso wemveliso:

Ukunyangwa kobushushu-Yindlela esebenzisa ukufudumeza kunye nokupholisa ukutshintsha iimpawu ezibonakalayo zemibhobho yebhoyili yoxinzelelo oluphezulu.Ukunyanga ukushisa kunokuphucula i-microstructure yetyhubhu yebhoyili ephezulu, ukwenzela ukuba kufezekiswe iimfuno zomzimba ezifunekayo.Ukuqina, ukuqina, kunye nokumelana nokunxiba ziimpawu ezininzi ezifunyenwe ngonyango lobushushu.Ukufumana ezi mpawu, sebenzisa ukucima & lt kunyango lobushushu;ikwabizwa ngokuba kukucinywa & gt;, ukucaphuka, ukucima & lt;ukunyibilika & gt;kunye nokuqina komphezulu, njl.

-

I-Bronze roll, iPhepha leCopper, i-Coil Sheet Coil, i-Copper Plate

Umboniso wemveliso:

Ubhedu olucocekileyo lubhedu olunomlinganiselo ophezulu wobhedu, kuba inxalenye ephambili yobhedu kunye nesilivere, umxholo ngu-99.5 ~ 99.95%;izinto eziphambili zokungcola: i-phosphorus, i-bismuth, i-antimony, i-arsenic, isinyithi, i-nickel, ilothe, isinyithi, i-tin, isulfure, i-zinc, i-oksijini, njl.;esetyenziselwa ukwenza izixhobo zokuqhuba, i-alloy yobhedu ephuculweyo, i-alloy-based alloy.

Ubhedu lwe-aluminium lunokwahlulwa lube ngamacandelo amabini.Enye iphosa i-aluminium yobhedu ukususa ukungcola kunye nokwandisa i-fluidity, i-alloy ayidluli i-0.5%;enye yeyokubumba ialuminiyam yobhedu ukunyusa uxhathiso kwi-corrosion, edla ngokusetyenziswa njengombhobho wokujiya, uluhlu lokwakheka ngokubanzi yi-Al1 ~ 6%, iZn 24 ~ 42%, kunye ne-Cu 55 ~ 71%.

-

Umtshintshi wobushushu ogqityiweyo ityhubhu

Umboniso wemveliso:

I-Wing tube exchanger heat exchanger yi-tubular heat exchanger enamaphiko, enokuthi yenziwe ngetyhubhu enye okanye ezininzi kwaye ingaba neqokobhe okanye iqokobhe.Ingumtshintshi omtsha wokushisa ofanelekileyo kwi-gas-liquid kunye ne-steam-liquid enokuthi yenziwe ngokwezifiso ngokwemiqathango yeparameter;I-fin tube licandelo elisisiseko le-fin exchanger ubushushu.Ukuze kuphuculwe ukusebenza kakuhle kokutshintshiselana kobushushu, iifins zidla ngokudityaniswa kumphezulu wetyhubhu yokutshintsha ubushushu, ukuze kwandiswe indawo yangaphandle yetyhubhu yokutshintsha ubushushu, ukuze kuphunyezwe injongo yokuphucula ukuhanjiswa kobushushu.

-

I-P235GH ST35.8 SA192 Umbhobho wentsimbi yeCarbon engenamthungo / Umbhobho weBoiler

Umboniso wemveliso:

Umbhobho we-boiler luhlobo lombhobho ongenamthungo.Indlela yokuvelisa iyafana nombhobho ongenamthungo, kodwa kukho iimfuno eziqinileyo zohlobo lwensimbi olusetyenziselwa ukuvelisa umbhobho wensimbi.Ngokutsho kobushushu bokusetyenziswa, yahlulwe kumbhobho webhoyila jikelele kunye nombhobho webhoyila woxinzelelo oluphezulu.

-

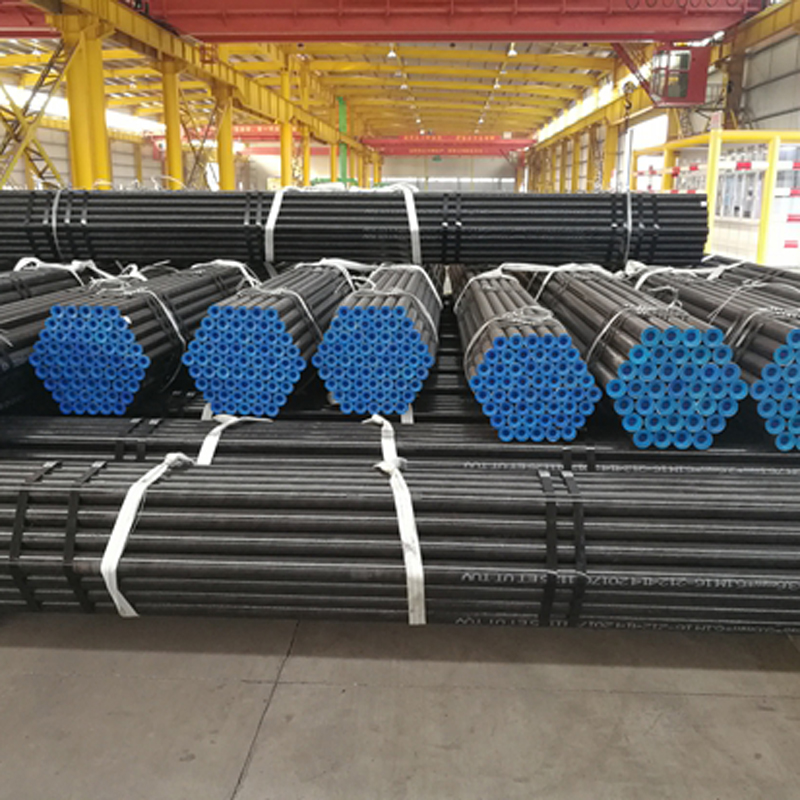

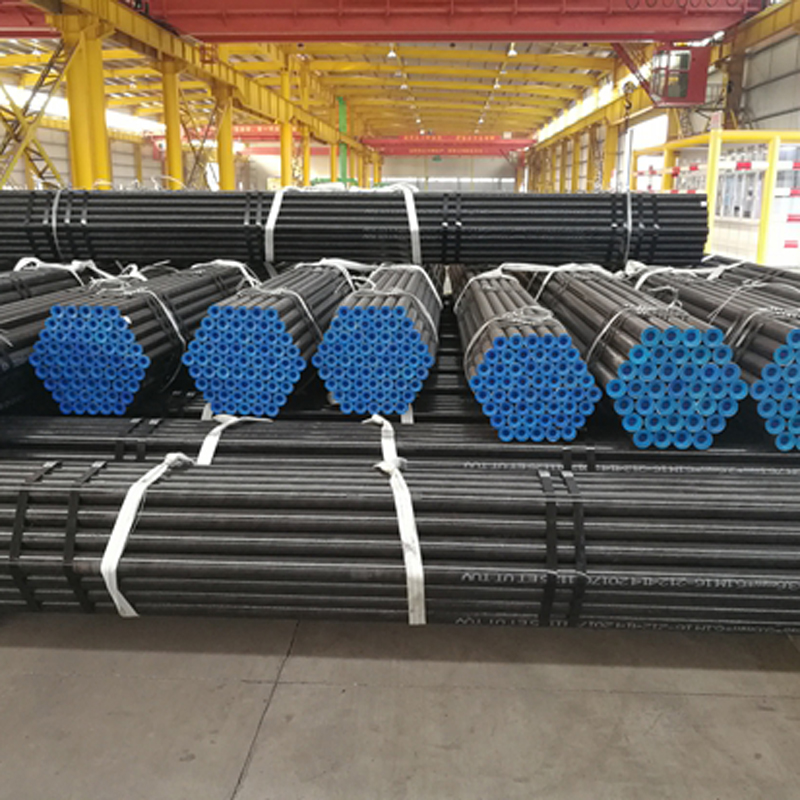

T11 T12 T22 T91 T92 Ingxubevange Steel Umbhobho Umthungo

Umboniso wemveliso:

I-alloy seamless steel pipe luhlobo lombhobho wensimbi ongenamthungo, ukusebenza kwawo kuphezulu kakhulu kunombhobho wensimbi ongenamthungo jikelele, kuba olu hlobo lombhobho wensimbi luqulethe uthelekiso lweCr.

Uninzi, ukuxhathisa ubushushu obuphezulu, ukumelana nobushushu obuphantsi, ukusebenza kokumelana nomhlwa akufani nenye ipayipi yentsimbi engenamthungo, ngoko ke ialloy pipe kwioyile, kushishino lweekhemikhali, amandla ombane, kwibhoyila kunye namanye amashishini asetyenziswa ngokubanzi.

Umbhobho wensimbi ongenamthungo uqulethe izinto ezifana nesilicon, manganese, chromium, nickel, molybdenum, tungsten, vanadium, titanium, niobium, zirconium, cobalt, aluminiyam, ubhedu, boron, umhlaba onqabileyo njalo njalo.

-

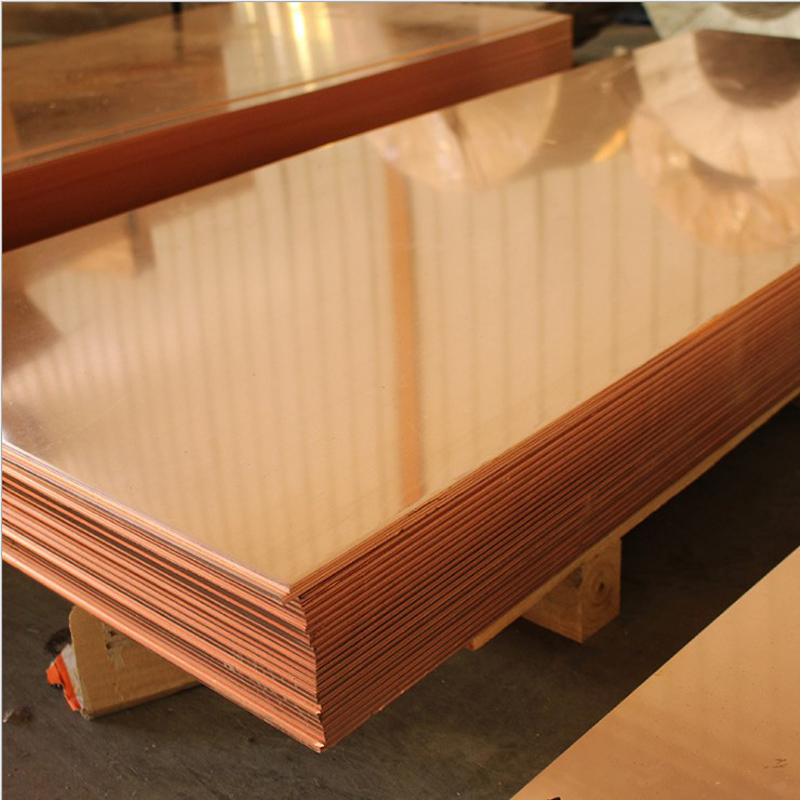

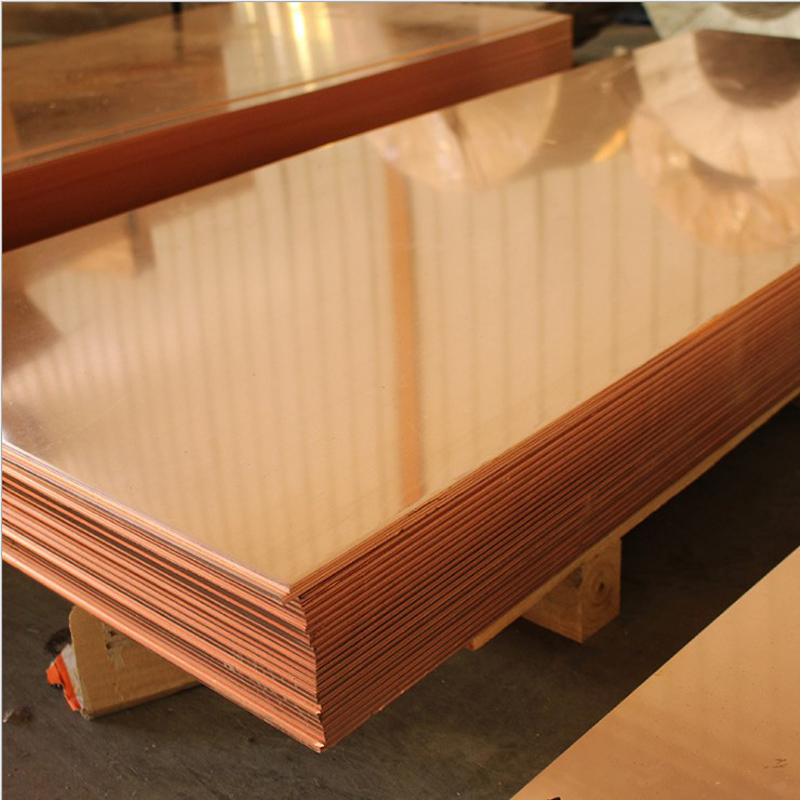

Icwecwe lobhedu, iPhepha leCopper, iCoil yePhepha leCopper

Umboniso wemveliso:

Cupronickel:

I-alloy yobhedu ene-nickel njengeyona nto eyongeziweyo.I-copper nickel ialloy ebizwa ngokuba yi-copper emhlophe eqhelekileyo ene-manganese zinc aluminiyam kunye nezinye izinto ze-alloy yobhedu emhlophe ebizwa ngokuba lubhedu olumhlophe.I-Industrial white copper yahlulwe ngokwesakhiwo sobhedu olumhlophe kunye nobhedu olumhlophe lombane ngamacandelo amabini.Ubhedu olumhlophe lwesakhiwo lubonakaliswe ngeempawu ezintle zoomatshini kunye nokumelana nokubola kunye nombala omhle.Olu bhedu lumhlophe lusetyenziswa kakhulu ekwenzeni izincedisi zeglasi ezichanekileyo, oomatshini beekhemikhali kunye namalungu enqanawa.Ubhedu olumhlophe lombane luneempawu ezilungileyo ze-thermoelectric.Ubhedu olumhlophe lweManganese olunomxholo owahlukileyo wemanganese sisixhobo esisetyenziselwa ukwenza isixhobo sombane esichanekileyo irheostor ukuchaneka kokuchaneka koxinzelelo lwegeji ye-thermocouple.

-

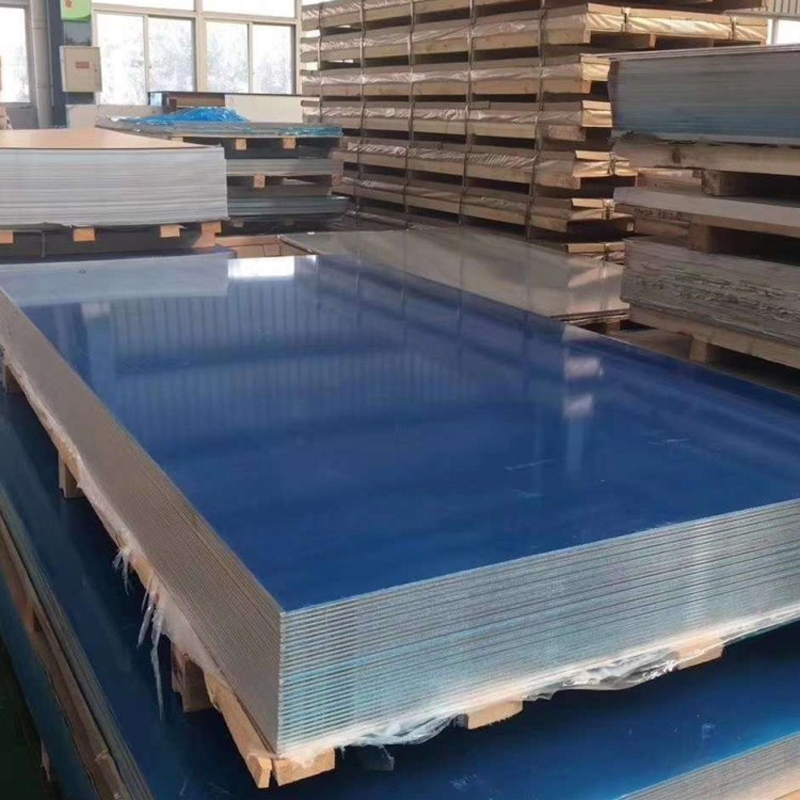

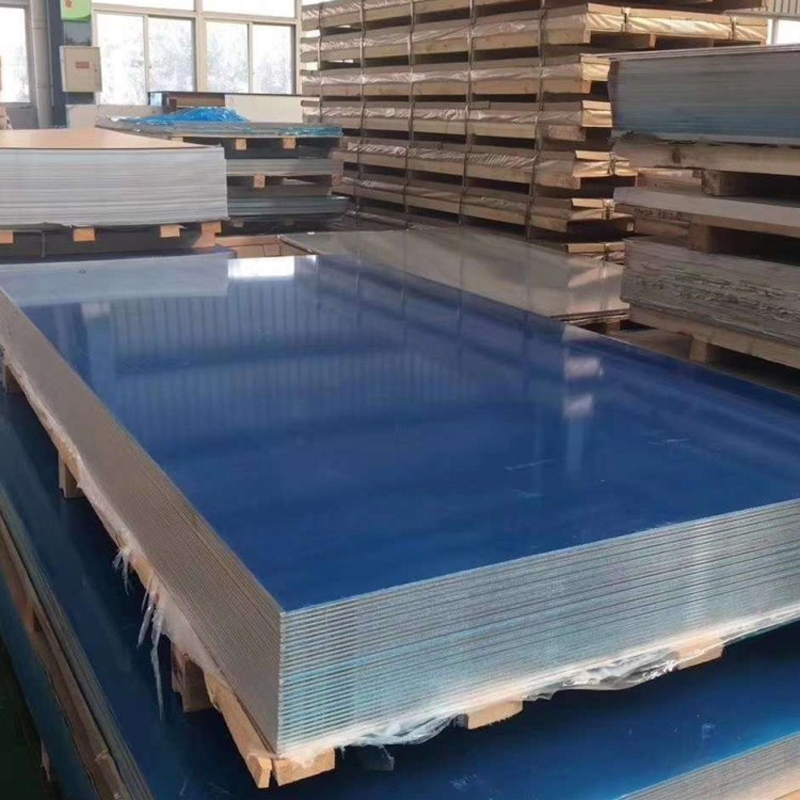

Ipleyiti yeAluminiyam / iAluminiyam icwecwe /7075/5052/6061

Umboniso wemveliso:

I-Aluminiyam i-alloy plate ngokwenkqubo yokwaleka inokwahlulwa ibe: iimveliso zebhodi yokutshiza kunye nebhodi yokugubungela kwangaphambili;

Ngokohlobo lwepeyinti lunokwahlulwa lube: i-polyester, i-polyurethane, i-polyamide, i-silicon eguquliweyo, i-fluorocarbon, njl.

Ipleyiti ye-aluminiyam enomgangatho omnye inokuba yipleyiti ye-aluminium ecocekileyo, ipleyiti ye-aluminium alloy ye-manganese kunye nepleyiti ye-aluminium alloy.

Ibhodi ye-aluminiyam ye-Forocarbon inebhodi yokutshiza ye-fluorocarbon kunye nepleyiti ye-aluminiyam ene-fluorocarbon yangaphambili.

-

Ikhoyili yentsimbi yeSilicon

Umboniso wemveliso:

I-Silicon alloy steel equkethe i-1.0 ~ 4.5% ye-silicon kunye nomxholo wekhabhoni ngaphantsi kwe-0.08% ibizwa ngokuba yi-silicon steel.Uneempawu ze-conductivity ephezulu yamagnetic, ukunyanzeliswa okuphantsi kunye ne-coefficient yokuchasana okukhulu, ngoko ukulahlekelwa kwe-hysteresis kunye nokulahleka kwangoku kwe-eddy kuncinci.Ikakhulu isetyenziswa njengeemathiriyeli zemagnethi kwiimotor, iziguquli, izixhobo zombane kunye nezixhobo zombane.Ukuze uhlangabezane neemfuno zokubethelwa kunye nokusika xa usenza izixhobo zombane, iplastiki ethile nayo iyadingeka.Ukuze kuphuculwe amandla okuchaphazeleka kwamagnetic kwaye kuncitshiswe ilahleko ye-hysteresis, okuya kusezantsi kobumdaka obuyingozi umxholo, kungcono, kwaye uhlobo lwepleyiti luthe tyaba kwaye umgangatho womphezulu ulungile.

-

304, 310S, 316, 347, 2205 UkuFakwa kwemibhobho eStainless

Umboniso wemveliso:

Izixhobo zoMbhobho zeStainless ziyigama eliqhelekileyo lamacandelo adibanisa, ukulawula, ukutshintsha, ukuguqula, ukutywinwa kunye nokuxhasa inkqubo yombhobho.Ukufakwa kombhobho yinxalenye edibanisa umbhobho kumbhobho.Izifakelo zombhobho woxinzelelo oluphezulu zifanelekile kwisixhobo somoya woxinzelelo oluphezulu, iikhemikhali zobushushu obuphezulu kunye nombhobho woxinzelelo oluphezulu, iplanti yamandla kunye neenqanawa zoxinzelelo lweplanti yamandla enyukliya, izixhobo zebhoyila ezinoxinzelelo oluphezulu kunye nokunye okusingqongileyo okukhethekileyo.Ukufakelwa kwemibhobho kusetyenziswa kakhulu kwiinkalo ezininzi zobunjineli ezifana nokwakha, ishishini lemichiza, imigodi kunye namandla.Indima yayo ebalulekileyo akufanele ihoywe.

-

Q355, P235GH, 210A1, T1, T11, T12 Round Bar Steel

Umboniso wemveliso:

Intsimbi ejikelezayo yintsimbi eqinile ye-cylindrical, ububanzi bayo bunokuthi buyilwe ngobukhulu obuhlukeneyo ngokweemfuno zemveliso.Inkqubo yokucubungula ibandakanya ukuqengqeleka okushushu, umzobo obandayo, ukubumba kunye nonyango lobushushu kunye nezinye iindlela.Phakathi kwabo, ukutshisa okutshisayo yinkqubo esetyenziswa ngokuqhelekileyo, enokuvelisa intsimbi ejikelezileyo kunye nobubanzi obukhulu.Inkqubo yokudweba ebandayo inokuvelisa i-diameter encinci kunye nokuchaneka okuphezulu kwentsimbi ejikelezayo.

-

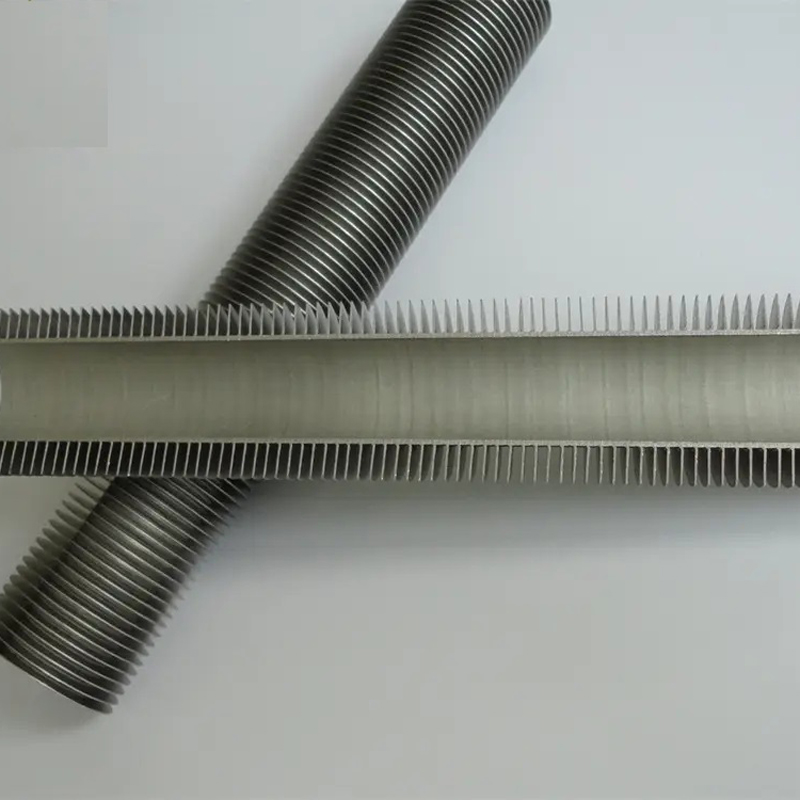

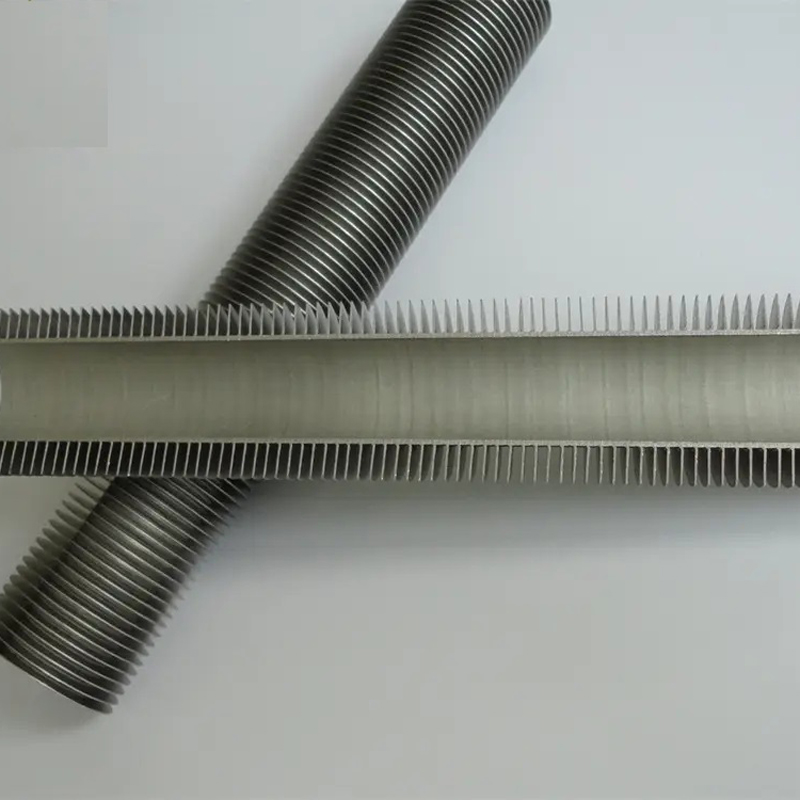

Ingxubevange yentsimbi yobhedu eStainless Fin Tube

Umboniso wemveliso:

Icandelo le-trapezoidal elenziwe nge-calendering ye-tube ye-fin ene-L iyahambelana nobukhulu bokusabalalisa ubuninzi bokuhamba kobushushu, kwaye icandelo lidityaniswe ngokusondeleyo kunye nokusebenza kakuhle kwe-thermal kuphezulu, okuphelisa ukuxhatshazwa kwe-thermal okubangelwa yicandelo. umsantsa.

Ubushushu bokusebenza: 230 ℃

Iimpawu: ukusetyenziswa kwenkqubo yokujija, ukusebenza kakuhle kwemveliso, umgama ofanayo, ukuhanjiswa kobushushu obuhle, umlinganiselo ophezulu wephiko, ityhubhu yesiseko inokukhuselwa kukhukuliseko lomoya.

Isicelo: ikakhulu esetyenziswa kwipetrochemical, amandla ombane, iphepha, icuba, ukufudumeza isakhiwo kunye namanye amashishini omoya opholileyo, isifudumezi-moya kunye noshishino lokutya lweprotein yesityalo somgubo, isitashi kunye nenye inkqubo yokutshiza yokutshiza yesifudumezi somoya.