I-SA588 SA387 iPlayiti yentsimbi yengxubevange

Impembelelo yezinto ze-alloy kwiipropathi zenkqubo yensimbi

1. Impembelelo yezinto ze-alloy ekusebenzeni kwensimbi

Iqondo eliphantsi lobushushu bemigca yesigaba esiluqilima kunye nolwelo kwaye incinci indawo yobushushu becrystallization, kokukhona kubhetele ukusebenza kokuphosa.Impembelelo yezinto ze-alloy kwintsebenzo yokuphosa ixhomekeke ngokukodwa kwimpembelelo yabo kwidayagram yesigaba se-Fe-Fe3C.Ukongezelela, izinto ezininzi, ezifana ne-Cr, i-Mo, i-V, i-Ti, i-Al, zenza i-carbide ephezulu yokunyibilika okanye i-oxide particles kwintsimbi, eyandisa i-viscosity yensimbi, ukunciphisa umbane, kunye nokuwohloka kokusebenza kokuphosa.

2. Impembelelo yezinto ze-alloy kwi-machining yeplastiki yentsimbi

Ukucutshungulwa kwePlastiki kwahlulahlulwe kukwenziwa kobushushu kunye nokusebenza okubandayo.Izinto ze-alloy kwisisombululo esiqinileyo, okanye ukubunjwa kwe-carbide (efana ne-Cr, i-Mo, i-W, njl.)Ukusebenza kwenkqubo ye-thermal ye-alloy steel jikelele kubi kakhulu kune-carbon steel.

3. Impembelelo yezinto ze-alloy kwiipropati ze-welding zensimbi

Izinto ze-alloy zonke ziphucula ukucinywa kwentsimbi, zikhuthaza ukubunjwa kwezicubu ezinqabileyo (i-martensite), kwaye zenze ukuba ukusebenza kwe-welding kube kubi.Nangona kunjalo, intsimbi iqulethe ixabiso elincinci le-Ti kunye ne-V, elinokuphucula ukusebenza kwe-welding yentsimbi.

4. Impembelelo yezinto ze-alloy kwi-steel cutting performance cutting ihambelana ngokusondeleyo nobunzima bensimbi, insimbi ifanelekile ukusika ukucutshungulwa kobunzima be-170 HB ~ 230 HB.Ukusebenza kokusika kwensimbi ye-alloy jikelele kubi ngakumbi kune-carbon steel.Nangona kunjalo, ukongezwa okufanelekileyo kwe-S, P, Pb kunye nezinye izinto kunokuphucula kakhulu ukusebenza kwentsimbi.

5. Impembelelo yezinto ze-alloy ekusebenzeni kwenkqubo yokunyanga ukushisa kwentsimbi

Ukusebenza kwenkqubo yokushisa ukushisa kubonisa ubunzima bonyango lobushushu bensimbi kunye nokuthambekela kwonyango lokushisa.Ikakhulu ibandakanya ukucima, ubushushu obugqithisileyo, i-embrittlement epholileyo kunye ne-oxidative decarbonization.Intsimbi ye-alloy ine-quenability ephezulu, kwaye indlela yokupholisa ecothayo ingasetyenziswa xa icinywa, enokunciphisa ukuguqulwa kunye nokuqhekezwa kwe-workpiece.Ukongeza i-manganese kunye ne-silicon kuya kwandisa uvakalelo olugqithiseleyo lwentsimbi.

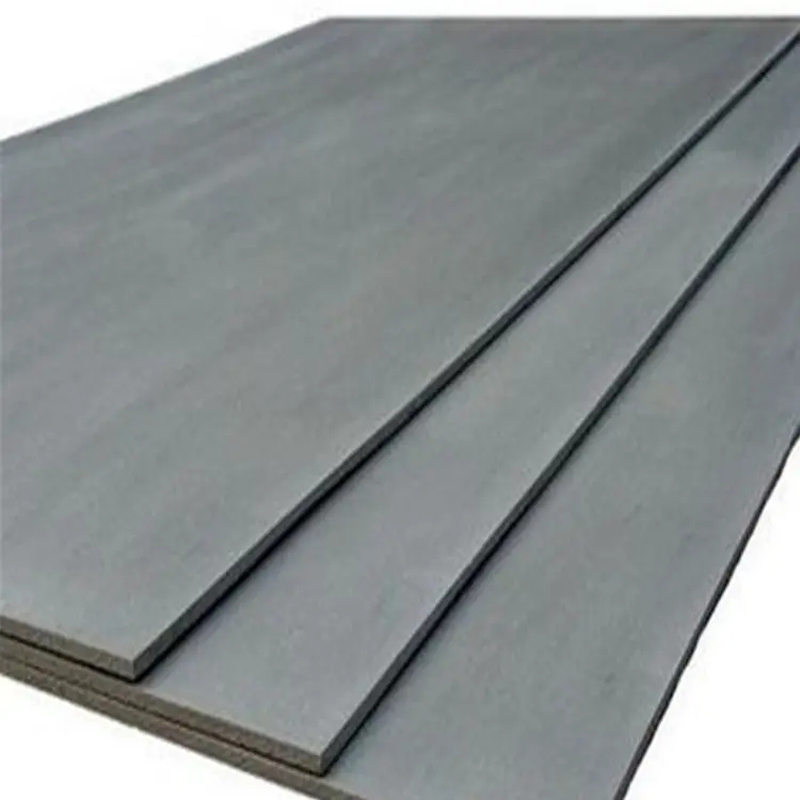

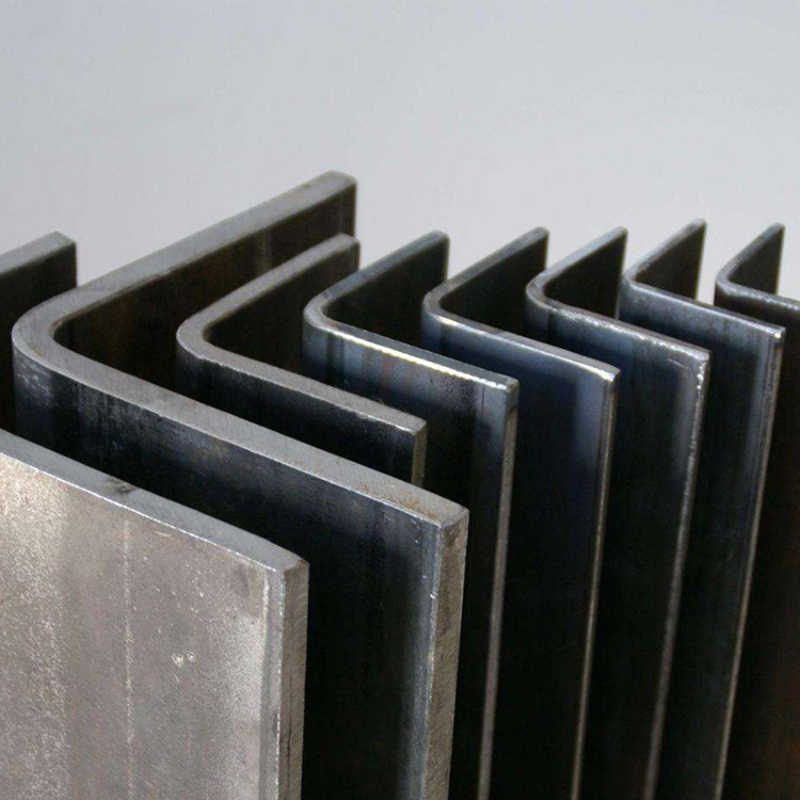

Iinkcukacha zeMveliso

| Ibakala lentsimbi: | 15CrMo, 12CrMoV, EN: S235JR, S275JR, S355JR, S420NL, S460NL, S500Q, S550Q, S620Q, S690Q I-ASTM: iBanga B, iBakala C, iBakala D, i-A36, iBakala 36, iBakala 40, iBakala 42, iBakala 50, iBakala 55, iBakala 60, iBakala 65, iBakala 70, iBakalaJIS:SPHC, SS400, SPFC, SPHD, SPHE |

| Umgangatho: | I-DIN EN 10083,ASME SA516, ASTM A203M,ASME SA588,ASME SA387,SAE1045 I-JIS G4051, AISI, BS |

| Ukutyeba: | 1.0-300mm |

| Ububanzi: | 100-4500mm, okanye ngokwesicelo esikhethekileyo somthengi |

| Ubude: | 1-20meters, okanye ngokwesicelo esikhethekileyo somthengi |

| Umqulu: | Thumela iPackage esemgangathweni |

| Isicelo: | 1.Amashishini, amashishini eenqanawa zoxinzelelo. 2.Isakhiwo seenqanawa, ukwakhiwa kweNjineli. 3.Imoto, iibhulorho, izakhiwo. 4.Ukwenziwa koomatshini, i-Pavement slab, njl. |

| IMill MTC: | Inikwe phambi kokuthunyelwa |

| Uhlolo: | Uhlolo lweqela leSithathu lunokwamkelwa,SGS,BV,TUV |

| Mount Port: | Naliphi na izibuko eTshayina |

| Ixesha loRhwebo: | FOB, CIF, CFR, EXW, njl. |

| Ixesha leXabiso: | TT okanye LC emehlweni |

| Iinkonzo zethu: | Sinokuyisika kwaye siyigobe ipleyiti yentsimbi ngokwemfuno yomthengi okanye umzobo, ukupakishwa ngokwesicelo sabathengi. |

Umboniso womzi-mveliso